1999년 스웨덴 말뫼에서 설립된 OctoFrost는 IQF 터널 냉동고, IF Chiller, IF cooker, If Blanchers 등 IQF 가공 풀라인을 제조 공급하는 회사입니다.

Octofrost는 고객의 요구사항을 지속적으로 최신 장비에 반영하여 최고의 IQF 장비 제조사로써의 위치를 고수하고 있습니다.

Octrofrost는 과일, 야채, 딸기, 해산물, 육류, 가금류, 파스타, 유제품 및 곡물과 같은 제품의 가공에 집중하고 있습니다.

Octrofrost는 전 세계의 고객사와의 상호 작용을 통한 단순한 구매 이상의 고객 가치 상승과 품질 향상에 적극적으로 협조하고 있습니다.

FRUITS

&

BERRIES

MEAT

&

POULTRY

ALL

PIZZA

TOPINGS

VEGETABLES

SEAFOOD

PASTA,

CHEESE

&

GRAINS

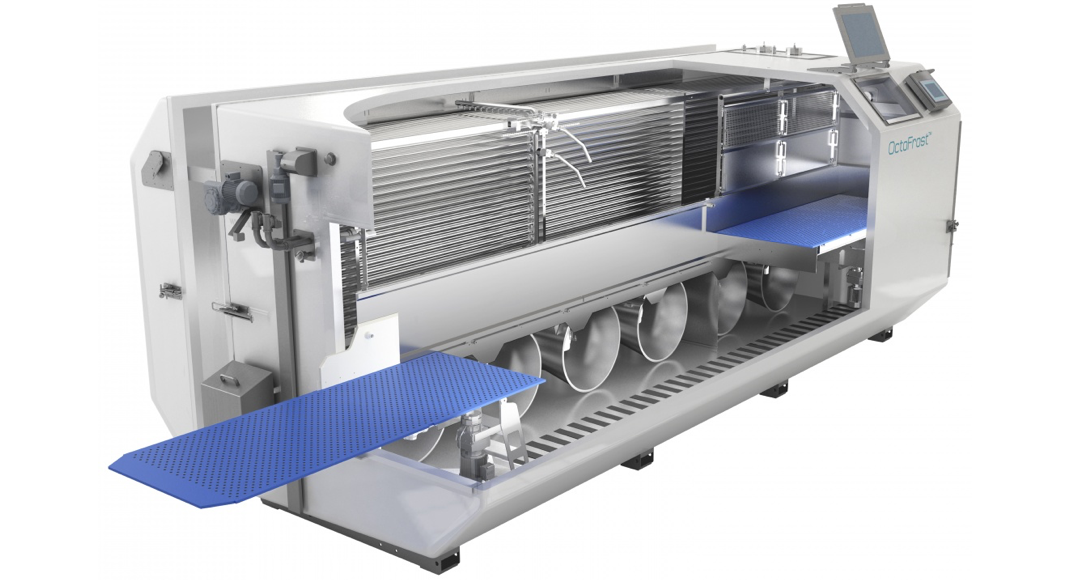

Features and Benefits

- 설치 공간 최소화 (공간대비 생산성 최대)

- -OctoFrost의 IQF는 기타의 타 제조사 IQF 설비대비 최소의 공간만이 필요합니다.

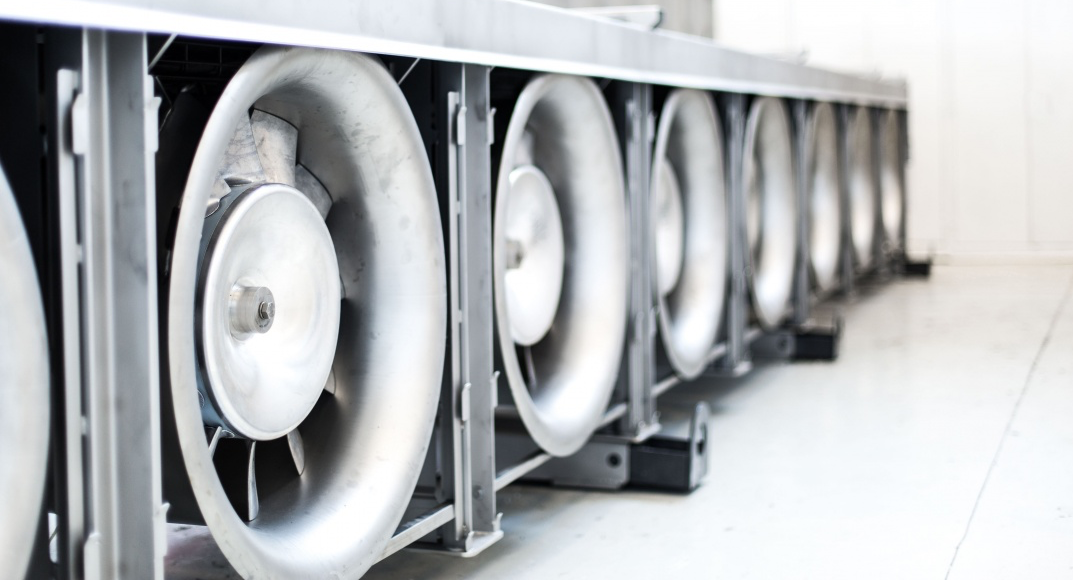

- 순환 기류를 통한 제품 이격 및 원물 상태 보존

- -제품의 분리 → 제품 표면 동결 → 심화 동결 건조

- 원물 상태 보존

- -원물의 형상, 색상, 향 및 맛 등의 보존이 월등합니다.

- 서리 제거 시스템 (SRS)

- -생산 중에도 가동되는 에어 나이프로 냉각 코일에 발생하는 서리 제거, 생산 효율 유지합니다.

- 내부 세척 접근성

- -세척 시 작업자가 내부 어느 곳이라도 세척이 가능하도록 접근성이 반영되어 있습니다.

- Bed Plate (내부 원물 이송 PLATE)

- -Bed Plate의 빠른 분리로 작업의 교체 및 세척 시간 단축에 효과적입니다.

-판구조로 벨트 구조 대비 유지보수의 비용이 현저히 낮습니다. - 자동 소독 기능

- -세계적인 세척 전문 업체와 협업으로 내부 자동 세척 및 소독 기능이 적용되어 있습니다.

Models

| MODEL | Nominal capacity* | Options |

|---|---|---|

| Model 2/1 | 1350 kg/hr, 2970 lbs/hr | Left-hand Right-hand |

| Model 3/2 | 2000 kg/hr, 4400 lbs/hr | Left-handRight-hand |

| Model 4/2 | 2600 kg/hr, 5720 lbs/hr | Left-hand Right-hand |

| Model 5/2 | 3300 kg/hr, 7260 lbs/hr | Left-hand Right-hand |

| Model 6/2 | 4000 kg/hr, 8800 lbs/hr | Left-hand Right-hand |

| Model 7/2 | 4650 kg/hr, 10230 lbs/hr | Left-hand Right-hand |

| Model 8/2 | 5300 kg/hr, 11660 lbs/hr | Left-hand Right-hand |

| Model 9/2 | 5900 kg/hr, 12980 lbs/hr | Left-hand Right-hand |

| Model 10/2 | 6600 kg/hr, 14520 lbs/hr | Left-hand Right-hand |

| Model 11/2 | 7300 kg/hr, 16060 lbs/hr | Left-hand Right-hand |

| Model 12/2 | 8000 kg/hr, 17600 lbs/hr | Left-hand Right-hand |

| Model 13/2 | 8600 kg/hr, 18920 lbs/hr | Left-hand Right-hand |

| Model 14/2 | 9300 kg/hr, 20460 lbs/hr | Left-hand Right-hand |

OctoFrost 3D Simulator (Windows)

CLIENTS