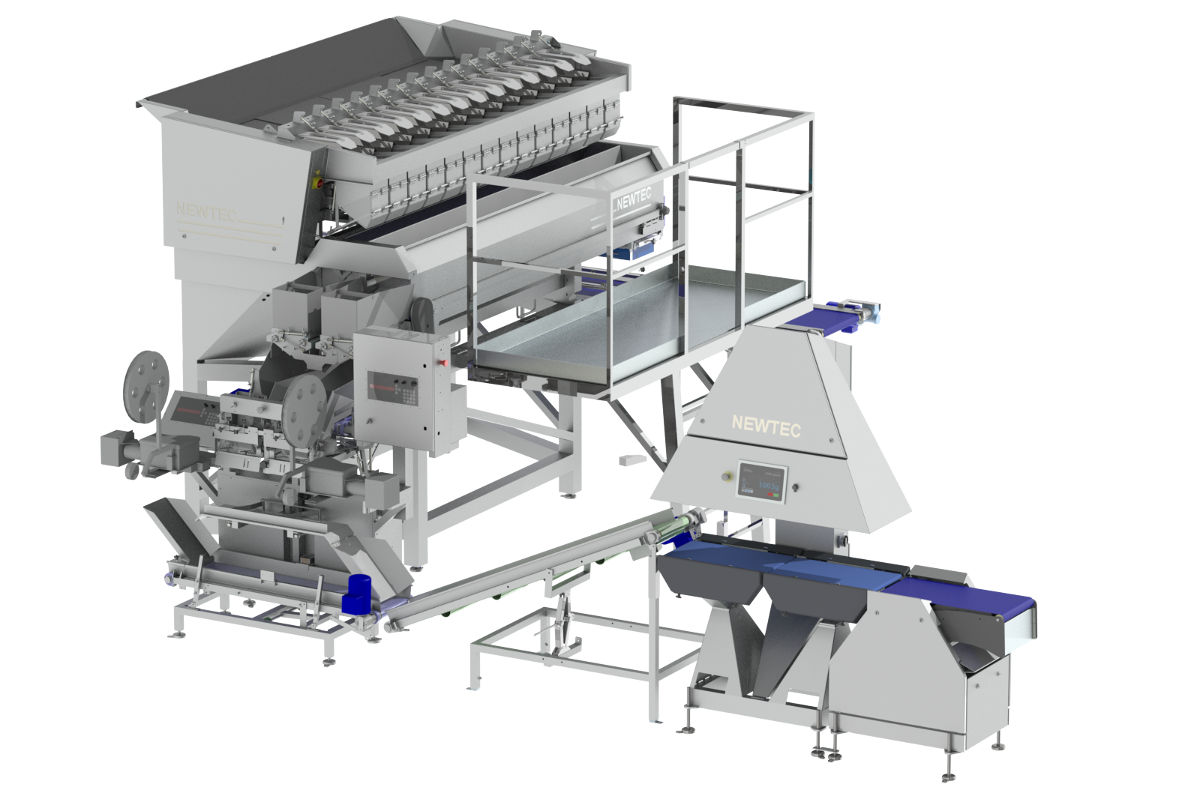

Weighing and bagging system for potatoes

Delivery April 2016

Product Potatoes

Portion sizes

- Wicketed bags: 2-5 kg

- Sacks/boxes: 10-20 kg

Packing Wicketed bags, sacks and boxes

Capacity for wicketed bags Up to 50 bags/min

Machines included

- Newtec weighing machine, model 4014XB1

- Newtec checkweigher, model QC90-2-DR, incl. drop down reject (retractable belt servo)

- Newtec bagging machine, model PEB60/KL

- Sack clamp system

- Floor frame and service platform

- Portion Collecting System (PCS), two cross conveyors - one left and one right, swing plate and control box

Challenge

Our customer is offering potatoes in smaller portions packed in wicketed bags and potatoes in larger portions, packed in sacks or boxes. They were therefore interested in a very flexible weighing and bagging solution for their potatoes. They wanted a three-in-one solution with a bagging system for wicketed bags, an option for manually filling of sacks and an option for packing in boxes.

Solution

Our weighing machine, model 4014XB1, with 14 weigh heads was chosen to achieve high speed and because it is extremely suitable for large products. The portion size ranges from 2-20 kg.

A very important part of the solution is the customised portion collecting system that meets the customer request of various packing solutions. With our bagging machine, model PEB60/KL on the left side, our customised solution provides a bagging system for wicketed bags on one side. When requested, manual filling of plastic sacks can take place on the right side. Our box filler, model HBC-4M, mounted with wheels can easily be connected to the PCS and moved again for a quick changeover when packing in sacks is planned.

Our bagging machine, model PEB60/KL is prepared for Kwik Lok closing according to customer request.

Equipped with our state-of-the-art vision systems, the included Check Point measures and evaluates a whole range of criteria in addition to weight, such as checking the packaging material and the product orientation on the belt. Newtec’s Check Points are pre-set by the operator to identify and reject any packaging that does not meet the requirements, with regard to size, colour and shape.

The overall result is a very flexible solution with high speed that enables our customer to change very quickly from one packaging to another without losing valuable production time and without worrying about quality control.

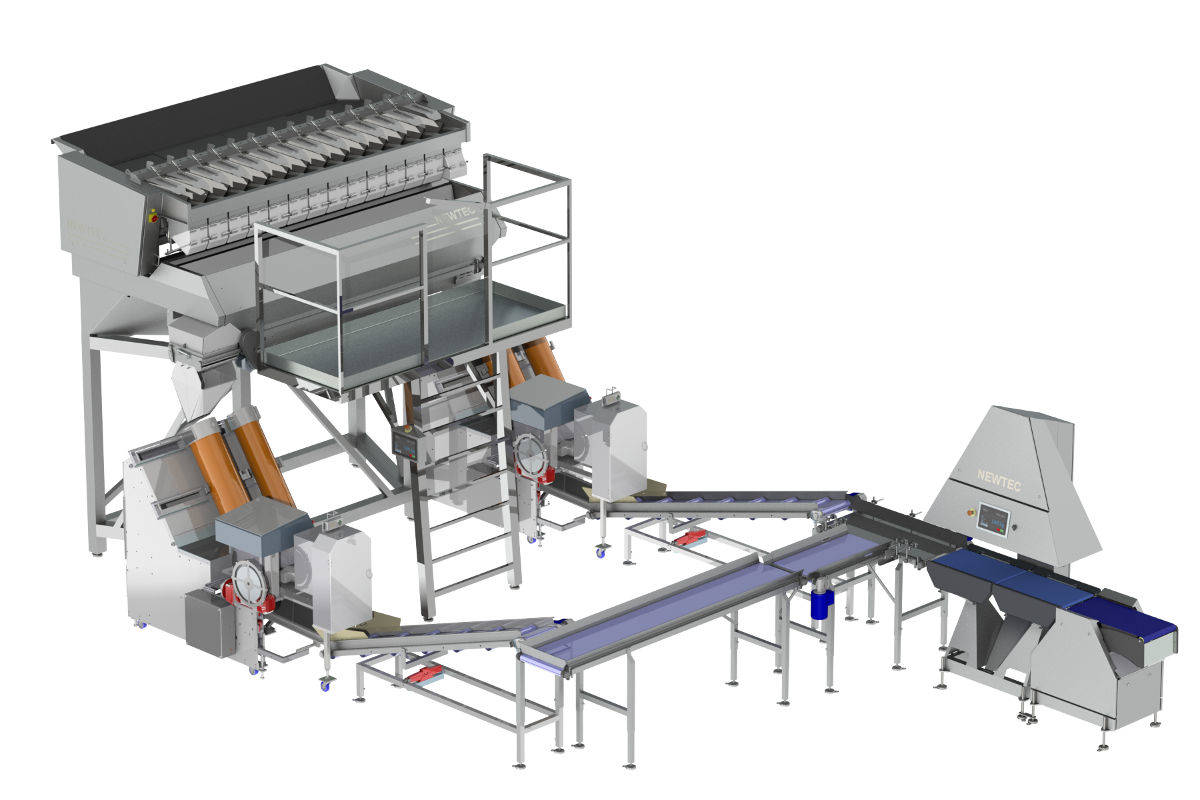

Weighing/packing line with two net clipping machines

Delivery May 2014

Product Onions packed in nets

Portion sizes 1, 1.5, 2 kg

Partner C-Pack

Capacity approx. 75-80 portions/min.

Machines included

- Newtec combination weighing machine, model 4014XB1

- Feeding 2 C-Pack VAC929 net clipping machines

- A Check Point, model QC90-2-DR-LR

- Portion Collecting System (PCS)

Challenge

Many of our customers request a specific solution in terms of packaging and capacity, which is why we thrive to make it easy for them to choose from our solutions. Our challenge in this particular project was to design and time two conveyors, and since our customer wanted to include two C-pack VAC929 net clipping machines in a solution that could control the entire system, we had to design and precisely time two conveyors that could merge and feed a Check Point in a controlled and timely manner.

Solution

Our solution consists of a multi-head combination weighing machine - model 4014XB1, combined with two C-Pack VAC929 net clipping machines and a Check Point, model QC90-2-DR-LR.

The weigher chosen for this customised solution is part of our latest series of multi-head combination weighers. In order to feed each net clipping machine, we chose our reliable, high-speed multi-head weigher – model 4014XB1, with 14 large weigh heads. The weigher covers a range of 2 kg to 30 kg and guarantees a very accurate portion weight.

Combined with our unique Portion Collecting System, specially designed for gentle distribution, the solution ensures a high capacity of approximately 75-80 portions/min., all while gently handling products all the way to the net clipping machines.

Moreover, due to its robust construction, the model 4014XB1 can handle a very high capacity, and because our solution is designed with four outlets, it is able to offer high flexibility.

Newtec implemented a start/stop function on the belt as a way to not only place each net precisely alongside one another, but to also allow for seamless entrance onto the infeed belt on the Check Point.

Merging of the nets is controlled by the sensors on each conveyor.

As an extra advantage for our customer, our Check Point and multi-head combination weighing machine are connected by Newtec Machine Link. This feature enables the operator to control recipes on both machines through one, easy-to-use touch screen. Consistent configuration of the machines saves both time and money, eliminating the need for extra operators and allows for a more reliable machine operation.

With a link to WebServices , our customer is provided with thorough production analysis. The data enables them to optimise their Newtec machines and production lines, all while finding better ways to earn the optimum from every single product. Should they require assistance from our Newtec service team, we link up to their Newtec machine and assist them directly.

Further orders

Our solution has successfully been in operation since 2014, and since then, our customer has ordered two more solutions.