JASA Vertical Packaging Machine

JASA 버티컬 포장기계는 식품 산업에서 다양한 제품 및 포장을 위해 사용되고 있습니다. 또한, 매일 10,000 가지 이상의 다른 패키지에 사용되고 있으며, 일반 재질의 포장지부터 특수 재질의 포장지까지 폭넓은 선택의 사용이 가능하도록 합니다. 특히 Bag-2-Paper™ 모델은 100% 종이 재질로 포장할 수 있기 때문에 100% 재활용이 가능한 친환경적 포장기계입니다.

다양한 포장 솔루션

10가지 이상의 포장형태

혁신적인 2-IN-1 Pack

Bag-2-Paper 100% 종이 포장

냉장, 냉동 진공 포장

Bag Shapes

(소스 포장 추가)

(종이재질)

"그 외 다양한 형태까지 원하는 모든 포장이 가능"

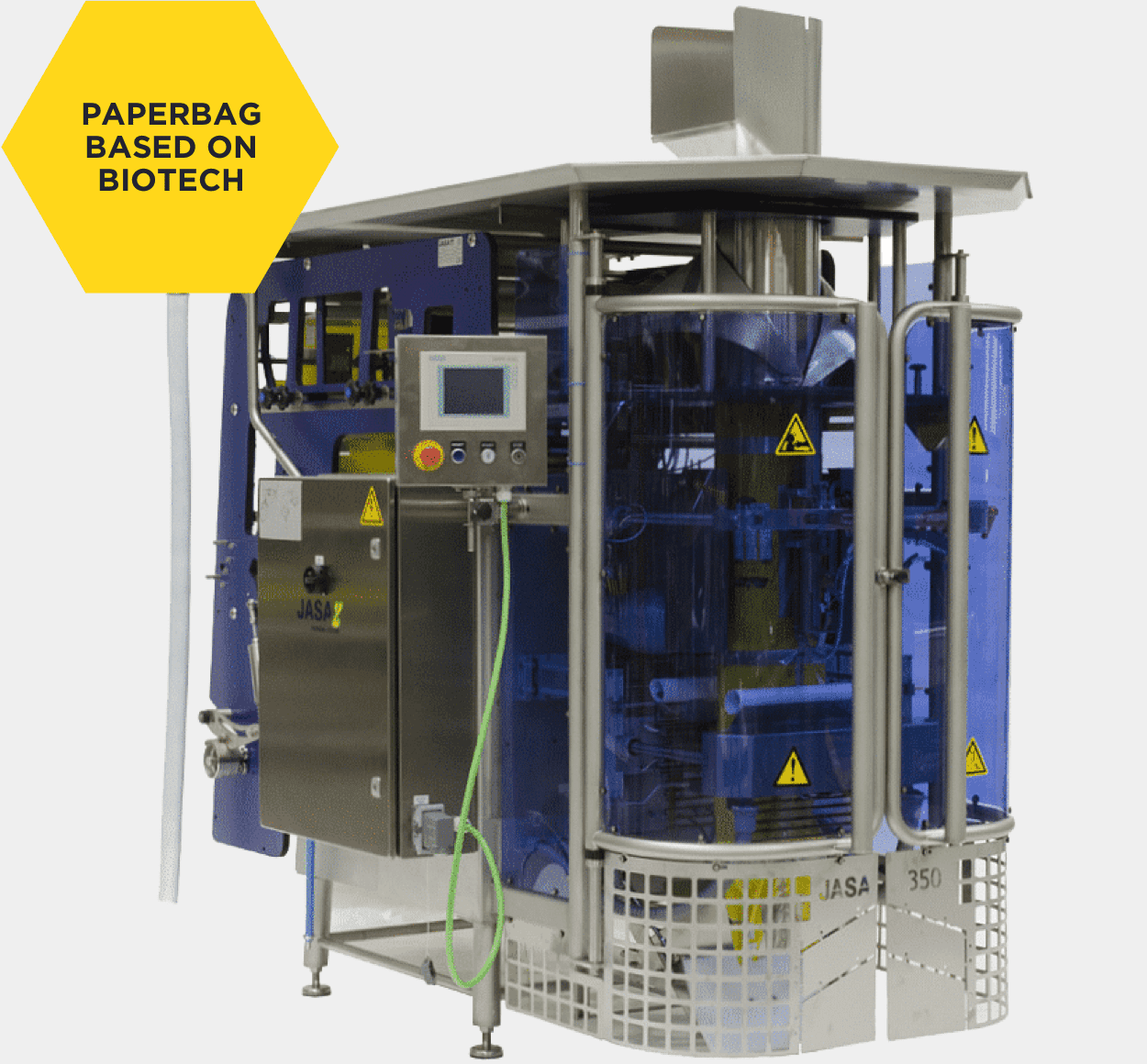

JASA JASA 350

The JASA 350 machine is suitable for packing bulk goods in bags from film on the reel. With some adaptions to the machine it can produce various bag styles. The constructions are in stainless steel and composite parts and therefor very suitable for the food-industry. The machine is equipped with an industrial PC operating system and if free programmable and very simple to operate by means of the JASA Display. Up to 100 programs can be memorized and selected.

- Constructions complete in stainless steel and composite parts

- Round forming set, size to be specified

- Film splice unit

- Printer frame for thermo transfer printer (standard)

- Eye mark controlled bag length

- Machine stop by end of film detection

- Industrial PLC operating system

- Up to 50 programs can be memorised and selected

- JASA Smart Display

- Synchronisation for most weighing and dosing systems

- Applications

Lemons, Limes, Oranges

Cherry & Plum Tomtatoes, Fresh Cut, Lettuces, Onions, Potatoes - Packing Specifications

Bag width 150 – 350 mm

Bag length, in one seal step up to 420 mm (longer in multiple seal steps)

Speed up to 50 pack/min. - Machine Dimensions

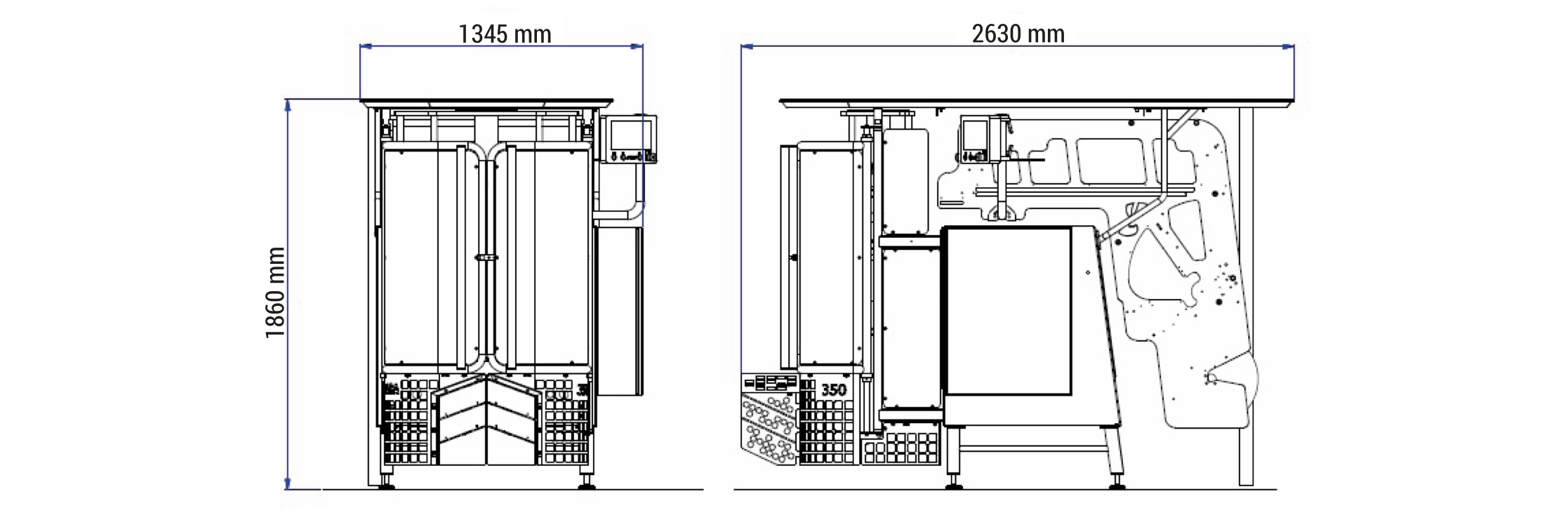

Length 2630 mm

Width 1345 mm

Height 1860 mm

Outside diameter film reel 450 mm

Net machine weight 775 kg - Electrical/air requirements

Electrical capacity 3kW, 3×400 VAC + N + PE, 50 HZ, others on request

Air requirements 6 bar

Air capacity (max) 370 l/min.

Bag Shapes

Pillow bag

Pillow bag

Gusseted bag

Gusseted bag

Vertisac

Vertisac

Doy pack

Doy pack

Block bottom bag

Block bottom bag

Bag Sizes

- Bag width min/max : 150 mm - 350 mm

- Bag length in one sealstep : 420 mm

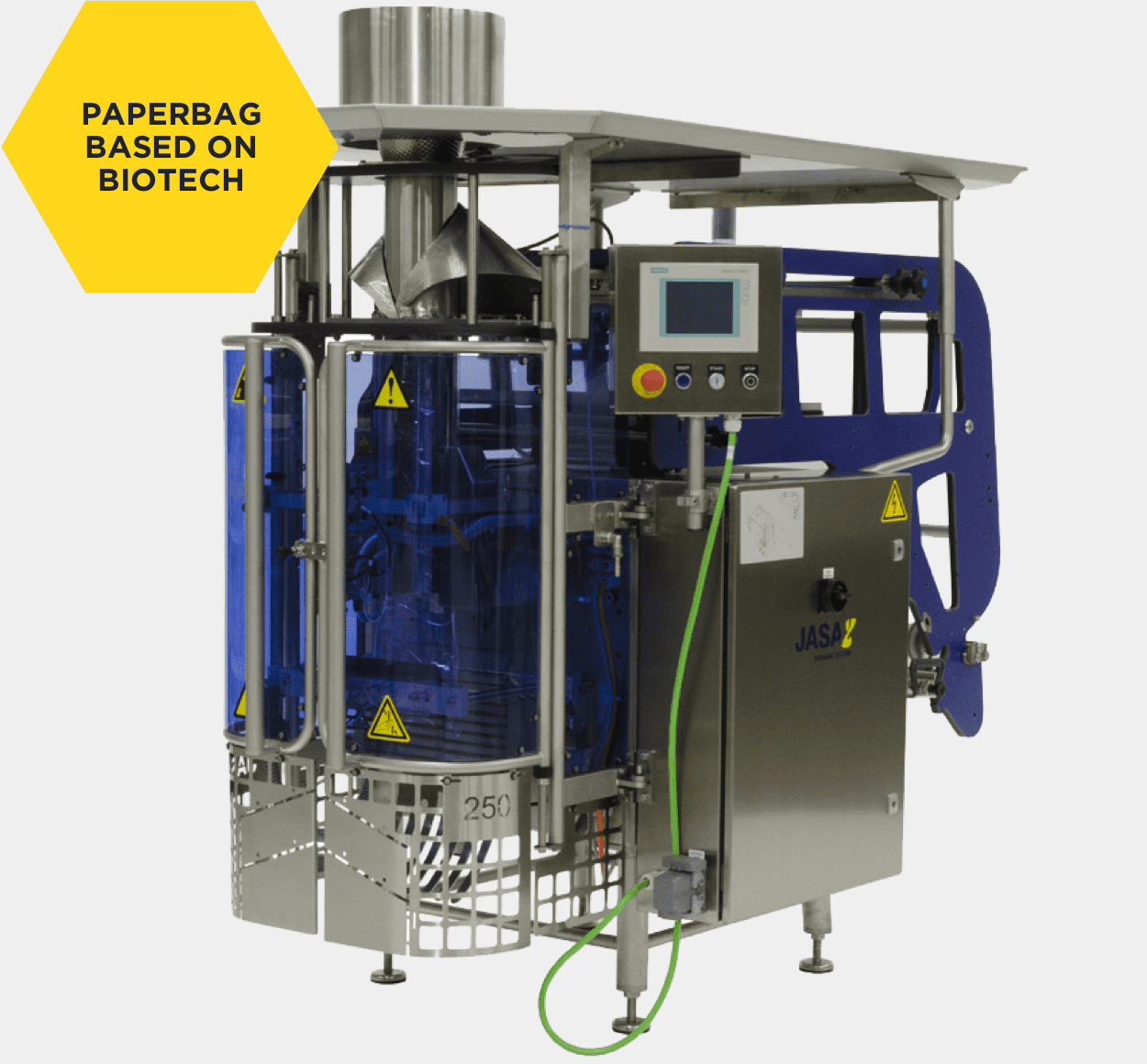

JASA JASA 250

The JASA 250 machine is very suitable for packing bulk goods in bags from film on the reel. The machine can produce various bag styles, by use of available options. The constructions of the machine are in stainless steel and plastic parts and therefore very suitable for the food industry.

- Constructions complete in stainless steel and composite parts

- Round forming set, size to be specified

- Film splice unit

- Printer frame for thermo transfer printer (standard)

- Eye mark controlled bag length

- Machine stop by end of film detection

- Industrial PLC operating system

- Up to 50 programs can be memorised and selected

- JASA Smart Display

- Synchronisation for most weighing and dosing systems

- Applications

Lemons, Limes, Oranges

Cherry & Plum Tomtatoes, Fresh Cut, Lettuces, Onions, Potatoes - Packing Specifications

Bag width : 150 – 350 mm

Bag length, in one seal step : up to 420 mm (longer in multiple seal steps)

Speed : up to 50 pack/min. - Machine Dimensions

Length : 2630 mm

Width : 1345 mm

Height : 1860 mm

Outside diameter film reel : 450 mm

Net machine weight : 775 kg - Electrical/air requirements

Electrical capacity : 3kW, 3×400 VAC + N + PE, 50 HZ, others on request

Air requirements : 6 bar

Air capacity (max) : 370 l/min

Bag Shapes

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Gusseted bag

Gusseted bag

Vertisac

Vertisac

Doy style

Doy style

Block bottom bag

Block bottom bag

Bag Sizes

- Bag width min/max : 80 mm - 250 mm

- Bag length in one sealstep : 420 mm

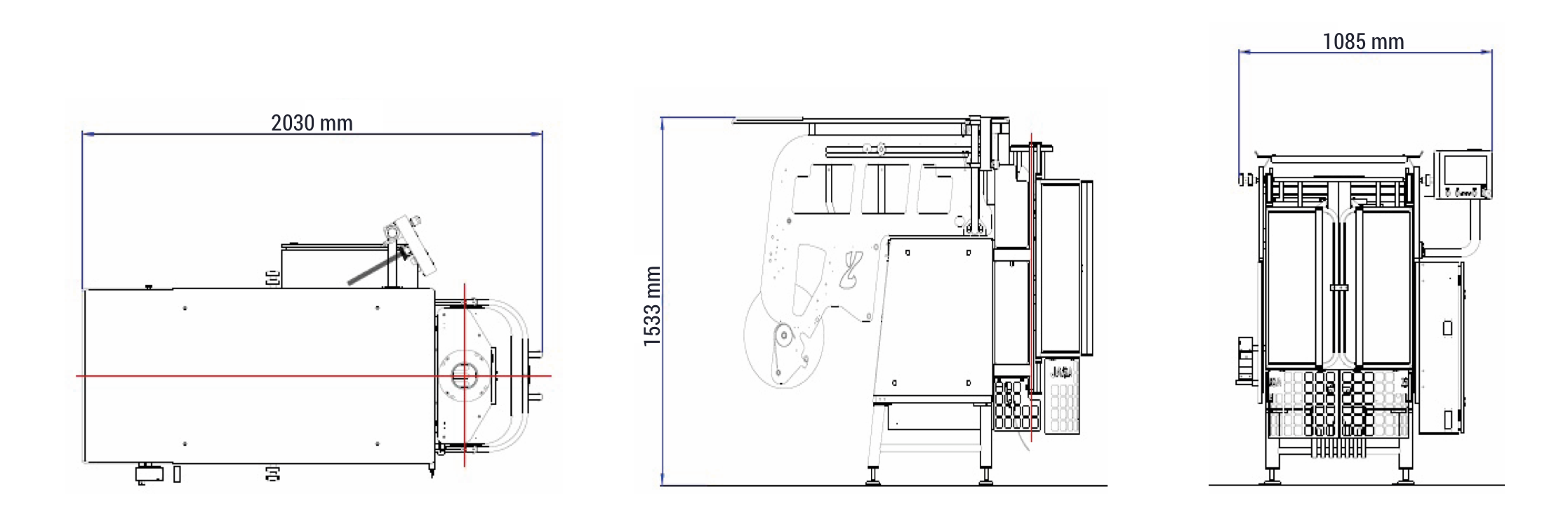

JASA PGS-50

The JASA SLEEVER slides prefolded and pre-glued printed sleeves around moulded trays. The JASA SLEEVER provides fruit, vegetable and fresh meal packagers with a versatile solution for fast, hygienic and space-efficient sleeving for a wide variety of trays.

- Hygenic design with Full Wash Down capability

- Full stainless steel construction

- Quick change sleeve magazine

- Adjustable sleeve positions

- Adjustable tray widths

- Compact footprint

- Available in single or double head models

- Works with plastic, fiber, cardboard and aluminum trays

- For the whole produce and fresh cut produce markets

- Applications

Lemons, Limes, Oranges

Cherry & Plum Tomtatoes, Fresh Cut, Lettuces, Onions, Potatoes - Transport Details

Size packaging : 120 x 100 x 190 cm

Pallet details : Pallet 120 x 100 cm

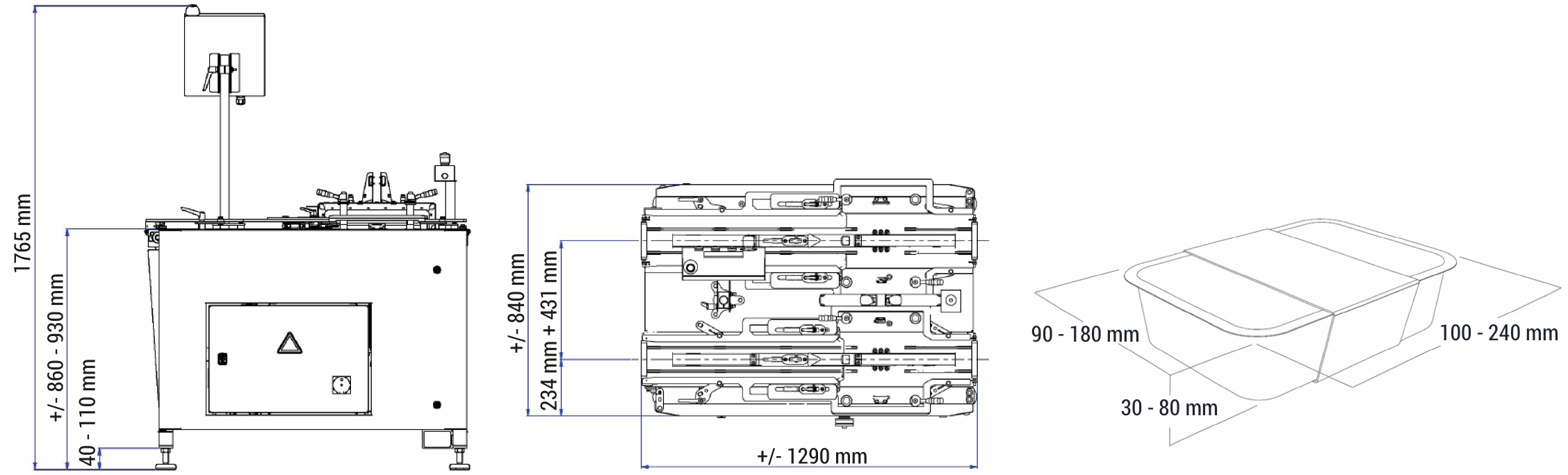

Gross/Net weight : 325 kg / 300 kg - Machine Dimensions

Length : +/- 1290 mm

Width : +/- 840 mm

Height : 1765 mm

Working height : +/- 860 - 930 mm

Foot height : 40 - 110 mm

Centre line conveyor belt(s) : 234 mm + 431 mm - Electric/Pneumatic Details

Electrical capacity : 1KW, 3x400 VAC + N + PE, 50Hz

Necessary air pressure : 6 bar

Pneumatic capacity : Approx. 560 L/min

Tray Shapes

Square

Square

Round

Round

Oval

Oval

Oblong

Oblong

Oblong

Oblong

Oblong

Oblong

Measurements Trays

- Width top : 90 mm - 180 mm

- Width bottom : 90 mm - 180 mm

- Length top : 100 mm - 240 mm

- Length bottom : 100 mm - 240 mm

- Height of tray : 30 mm - 80 mm

- Radius corners : at least 5 mm

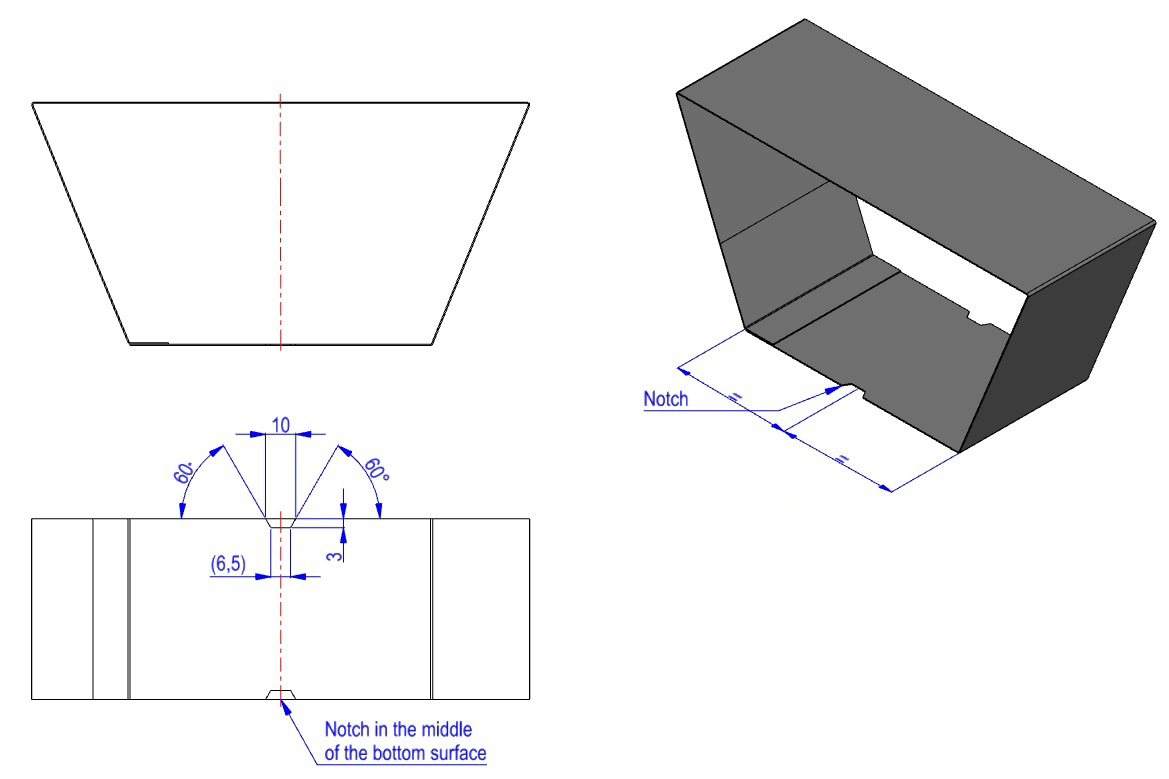

A slide-in guide groove is needed in the case of a radius of less than 20 mm

Deviating measurements may be presented for assessment - Direction transport : The short side is the guiding factor

Production Capacity

- 50 sleeves per minute

- Measurements Sleeves

Width : at least 60 mm / max. 110 mm (other sizes in consultation)

Length : 130 mm / 320 mm (other sizes in consultation)

Number of sleeves per cartridge : 250 - 300 (depending on the thickness of the cardboard) - Details Materials

Minimum thickness : 210 gr. cardboard

Maximum thickness : 400 gr. cardboard

Quality : GC-, GC-2, GT- and GD* * The sleeve must be adequately tested in the case of GD quality Direction of fibre : Always perpendicular to the fold/zip of the sleeve - Storage Conditions

Temperature : Approx. 18 ºC

Relative humidity : Approx. 50-55 ºC - Requirements Shape of the Sleeves

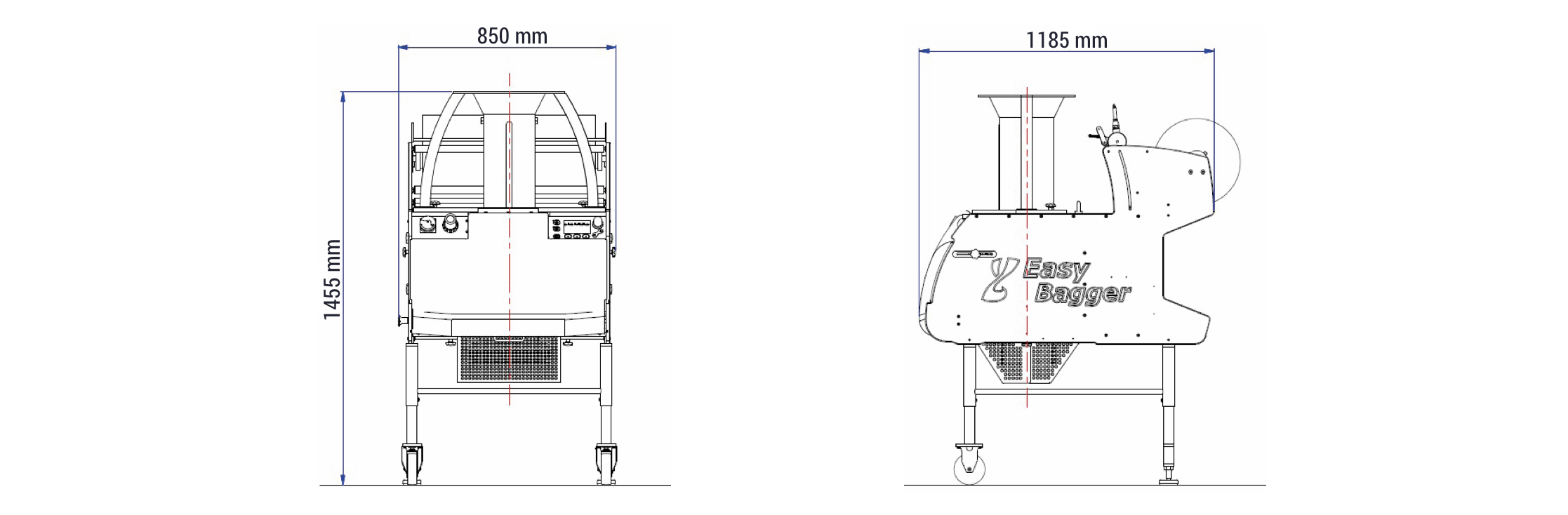

EASYBAGGER

The EASYBAGGER is an intermittent vertical form, fill and seal machine specially designed for a packaging process with small shifts of various products into flexible packs. The compact design of the machine makes it very easy to handle in small and flexible production circumstances. Due to the composite construction the machine is very suitable for the food industry. Machine operation is controlled by an industrial PC system and is free programmable and very simple to operate by means of a key operated display. Up to 100 programs can be memorized and selected.

- Horizontal and vertical heat sealing system for PP or laminated films

- Integrated electrical cabinet

- Forming set, size to be specified

- Applications

Lemons, Limes, Oranges

Cherry & Plum Tomtatoes, Fresh Cut, Lettuces, Onions, Potatoes - Packing Specifications

Bag width 150 – 350 mm

Bag length, in one seal step up to 420 mm (longer in multiple seal steps)

Speed up to 50 pack/min. - Machine Dimensions

Length 2630 mm

Width 1345 mm

Height 1860 mm

Outside diameter film reel 450 mm

Net machine weight 775 kg - Electrical/air requirements

Electrical capacity 3kW, 3×400 VAC + N + PE, 50 HZ, others on request

Air requirements 6 bar

Air capacity (max) 370 l/min.

Bag Shapes

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Pillow bag

Gusseted bag

Gusseted bag

Gusseted bag

Gusseted bag

Bag Sizes

- Max bag width : 350 mm (13.78 in)

- Max bag length in one seal step : 220 mm (8.66 in)

Production Capacity

- Up to 25 bags/minute

NEWTEC NBM

Versatile Packing Solutions

- High capacity – up to 90 packs per min.

- Customised according to packaging type and product

- Flexible dispenser system

- Gentle product handling with low drops

- ‘No punnet – no product’ system

- WebServices available for remote servicing and for capturing production data

- MachineLink enabled - from only one touchscreen, either on our NBM or our weighing machine, recipe change and start/stop for both machines is possible

Applications

For fruits and vegetables packed in punnets or clamshell punnets- Potatoes • Carrots • Tomatoes • Cherry tomatoes • Peppers

- Peaches • Similar fruits and vegetables

- Capacity: Up to 90 packs per min.(NBM-3S)

- Punnet dimensions (approx. range)*

- Max.: L: up to 340 mm, W: up to 300 mm, H: up to 150 mm

- Min.: L: approx. 100 mm, W: approx. 55 mm, H: approx. 40 mm

- Material: According to the EU rules on food contact materials.

- Air requirement:

- Connection: 3/8"

- Min. pressure: 6 bar (0.6 Mpa)

- Consumption: 350 NL/min.

- Electrical requirement: 3x230 VAC or 3x400 VAC (N), PE 50/60 Hz 2.5 kW

- Environment: 5 ºC – 40 ºC

- Weight: Approx. 450 kg

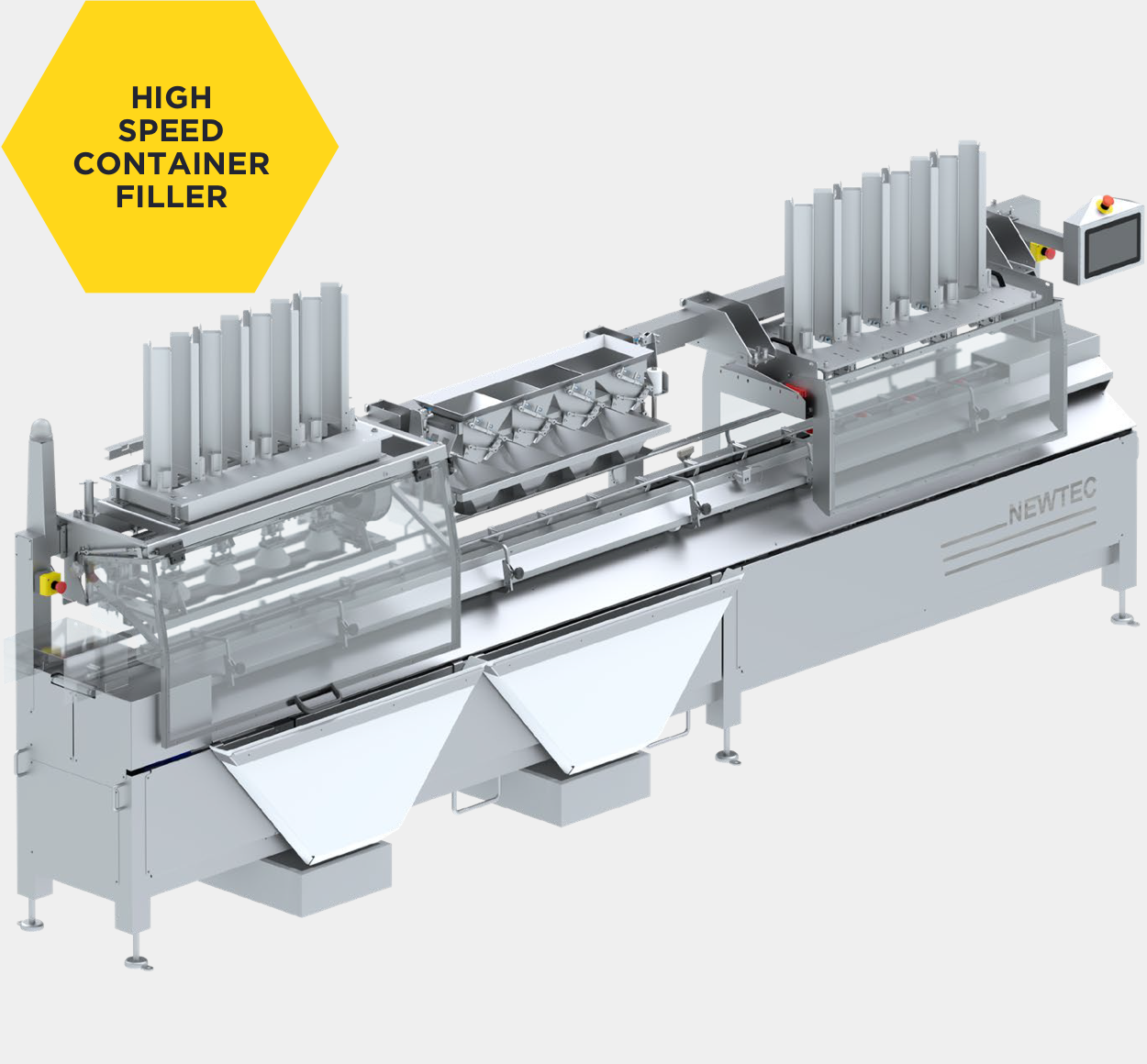

NEWTEC HSCF

Versatile Packing Solutions

- High flexibility (container type and size)

- High speed – up to 100 containers per min. (depending on container type and capacity of weighing machine)

- High flexibility with low changeover time

- Gentle product handling – also for fragile and delicate products

Applications

Various convenience food such as:- Cherry tomatoes and other fresh vegetables

- Mixed nuts

- Healthy candy

- Other ready-to-eat products

- Speed: Up to 100 containers per min. (depending on container type and capacity of weighing machine

- Capacity: Portion weight up to 1000 g

- Material: According to the EU rules on food contact materials

- Air requirement:

- Connection: 3/8"

- Min. pressure: 6 bar (0.6 Mpa)

- Consumption: 250 NL/min.

- Electrical requirement: 3x230 VAC or 3x400 VAC (N), PE 50/60 Hz 2.5 kW

- Environment: 5 ºC – 40 ºC

- Weight: Approx. 800 kg